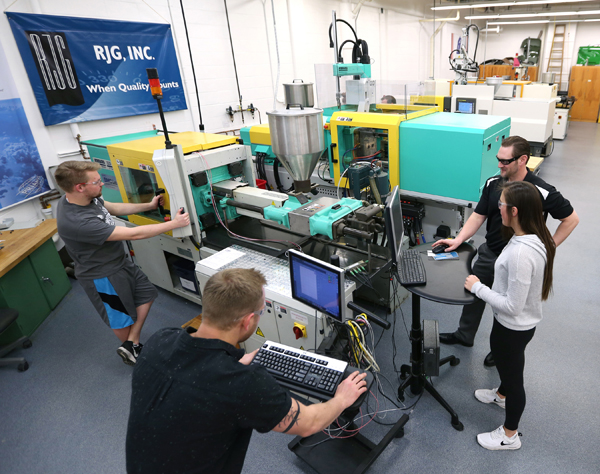

When students step into the plastics engineering lab at University of Wisconsin-Stout, they are working with state-of-the-art equipment.

Three companies recently installed or will be installing new electric injection molding machines in the lab in Jarvis Hall Technology Wing. Total value is about $500,000, according to Professor Adam Kramschuster.

“We have one of the premier labs in the U.S., and it’s because the industry values this program and wants to get information about their equipment in here for our students,” Kramschuster said.

The companies — Arburg, of Germany; Engel, of Austria; and Milacron, of Ohio — are industry leaders who make machines for manufacturers around the world.

The companies’ machines in UW-Stout’s lab are on consignment, with the plan to rotate in new machines every few years.

The companies’ machines in UW-Stout’s lab are on consignment, with the plan to rotate in new machines every few years.

“Supporting Stout is a logical thing for Arburg to do. We believe to grow effectively you need a highly skilled workforce both in house and at our customers’ facilities,” said Liam Burns, manager of Midwest Sales and Engineering for Arburg.

“After spending four years in the area and visiting with all the major plastics companies in the Minnesota, Wisconsin and Illinois area, I meet a Stout graduate in almost every location. The employers have always spoken very highly of the capability of the Stout graduates coming straight from the college,” Burns added.

Joachim Kragl, director of Advanced Molding Systems and Processing for Engel, said several of his company’s plastics manufacturing customers spoke highly of UW-Stout’s graduates, making it any easy decision to place a new machine at the school.

“Adam Kramschuster and his team are extremely motivated and passionate. The benefit for Engel is the early introduction of students and faculty personnel to our equipment and its capabilities,” Kragl said.

“To stay in touch with the latest and greatest processing technologies and being able to apply them in future job placements is absolutely crucial. Unfortunately, all too often students are taught on older equipment which creates a disconnect from actual available technology. Upon graduation, this skill set makes the student even more valuable to the industry,” Kragl added.

Burns said students need to be “up to speed” with the latest technology when they graduate. “In modern injection molding there is little room for error.”

The growing industry needs more skilled graduates. UW-Stout graduates in the program historically have reported 100 percent employment within a year.

“Being at the onset of the Internet of things — IoT — and the dawn of industry 4.0, the plastics industry finds itself at an exciting crossroads. At the intersection of classic manufacturing and information technology lies a vibrant challenge for plastics engineers. This will guarantee exciting job opportunities for the years to come,” Kragl said.

Kramschuster noted most consumer products contain injection molded parts, something that won’t be changing in the near future. UW-Stout students also learn plastics extrusion, which is used to make such products as piping, tubing and plastic sheeting, as well as other relevant plastics processing techniques.

Kramschuster noted most consumer products contain injection molded parts, something that won’t be changing in the near future. UW-Stout students also learn plastics extrusion, which is used to make such products as piping, tubing and plastic sheeting, as well as other relevant plastics processing techniques.

In addition to the three new electric machines, the plastics engineering program has several injection molding machines donated by local companies like SMC Ltd. of Somerset, Donatelle of New Brighton, Minn., and Flambeau Inc. of Baraboo.

“Plastic injection molding is used to create complex 3D shapes and is used to make a variety of common products like cell phones, sunglasses, computer housings, video game controllers, automotive interiors, recreational vehicle components, tractor components and a large portion of medical devices,” Kramschuster said.

Burns said “injection molding continues to grow, year after year, and we cover such a vast field of end products from automotive to medical to packaging, etc., there is always something new coming along. We are an industry that offers high paying jobs in almost any region of the country and a knowledge that can be transferred across all industries.”

Four UW-Stout plastics engineering majors, all seniors, are excited to be using the new equipment.

Hunter Bartz, of White Bear Lake, Minn., is working with the machines and lab software for his capstone project. “Our lab is state of the art, and we have access to more machines and testing equipment than any university I have heard of. This equipment is setting me up for success long and short term in my career …and gives me a fundamental advantage over other job candidates upon graduation.”

Bennett Conrardy, of Burlington, called UW-Stout’s lab “amazing. We have some of the newest technology available. I am extremely grateful to have this lab and all of its resources at my fingertips.” During an internship, he used his experience from UW-Stout to help an engineer develop a new process. “It was really awesome applying what I learned from using the Milacron press during my lab to real-world problems.”

Corey Kuepper, of Menasha, said the new machines provide opportunities for “lots of hands-on experience and getting familiar with the interfaces. Most likely, after college I will be working on some of these machines, so it is nice to get some knowledge on them while attending college.”

Riley Wittmann, of Menasha, said the lab has “such a wide variety of injection molding machines” that give students an advantage when they graduate. “These electric machines have taught me how to do maintenance, processing and trouble-shooting for injection molding machines.”

UW-Stout’s plastics engineering Bachelor of Science program is one of only two ABET-accredited programs in the U.S. Students learn product and mold design, plastics materials science and advanced processing techniques.

###

Photos

From left, Professor Adam Kramschuster talks with students Hunter Bartz, Bennett Conrardy and Jacob Halling next to a 55-ton Milacron Roboshot injection molding machine in the plastics engineering lab.

Students work with injection molding machines in UW-Stout’s plastics engineering lab in Jarvis Hall Technology Wing. Partnerships with three companies have given the lab three state-of-the-art machines.

Plastics engineering major Bennett Conrardy programs a machine in the plastics engineering lab at UW-Stout.